Extremely powerful nesting

Nest hundreds or even thousands of components for the absolute best efficiency. Schedule days of work to maximise your machine throughput.fil

Sheet Metal or Composites

Specific features provide unique benefits to both composite and sheet metal manufacturers, delivering a demonstrable return on investment.

Highly efficient nests

Extremely aggressive algorithm suited to large numbers of dissimilar nest parts.

Time-based nesting

By allowing the nester to run for longer periods you can get highly optimized nest patterns.

Multi-sheet nesting

Run large numbers of parts over multiple sheets, including different sizes.

Specify sheets to run

Generate fewer programs for the operator to load using 'Prefer Less Layouts' feature.

Optimized cutting path

Features such as intelligent lead-ins and common cutting minimize cutting time.

Powerful feature integration

Existing JETCAM features such as heat avoidance and JET-Cut Fly Cutting and JET-Optimizer work seamlessly.

Remnant support

Include material remnents, specifying whether they should be used first or last, and also whether to sort by size.

Improve laser part quality

'Automatic spreading of parts' ensure that once maximum material efficiency has been achieved, parts within parts are spread out, dissipating heat and improving quality.

Nest hundreds or even thousands of components for the absolute best efficiency. Schedule days of work to maximise your machine throughput.fil

Industries such as composites can generate nests measuring hundreds of metres in length. UPN can literally nest thousands of components, including across multiple material lengths - extremely useful for composite users with static length tables.

When combined with CrossTrack or JOC, UPN allows 'assemblies' to be grouped together, but you can also specify a maximum distance for composite plies to be nested within preceding assemblies - this provides a balance between material efficiency and easier unloading/sorting after cutting.

Choose between maximum nesting efficiency or fewer NC code changes, running nests multiple times. Toggle the 'Prefer Less Layouts' option between none, little, normal, strong or aggressive preference for maximum flexibility.

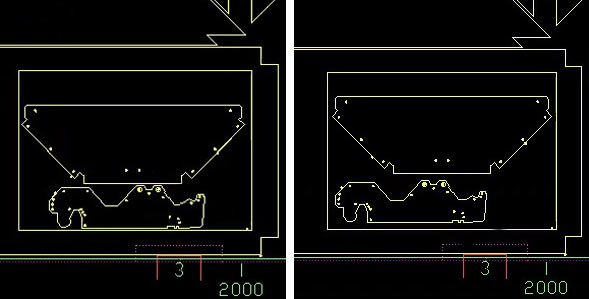

Parts nested within parts can be spread automatically (pictured right), improving cutting quality and reducing heat problems.

'Automatic Spreading of Parts' take advantage of available material when nesting parts within parts, improving cutting quality and reducing potential heat problems without impacting on material efficiency.

How much would just a 1% material saving make for your business. Many customers that take the 60-day trial see most or even all of the cost of UPN repaid before the trial is even over, meaning that you start saving money before you've even paid for the upgrade!

UPN is an optional nesting module that can be added to JETCAM Expert Premium with Nesting Interface to automatically create highly optimized nests. You can specify a predetermined period of time for the nester to continue to try different patterns.

Most of the settings are the same for both, but UPN has some unique strengths. For example, multi-sheet nesting performs differently, allowing UPN to generate nests on different sheet sizes that can be run multiple times, versus generating all unique nests. UPN is faster, especially when working with larger, denser nests, such as the composite industry. It also have features specific to certain technologies, such as automatic spreading of parts for laser users - ensuring that once the maximum nest density has been achieve it will spread parts within holes, ensuring less heat build up and a better quality part.

Yes. You can choose to purchase one, other or both nesting options, and can run patterns on both nesters to see which will deliver the best efficiency over a given period of time.

Trials are for existing customers only, but we do provide a free nesting benchmark for prospects. The minimum specification system is Expert Premium with Nesting Interface. If you do not have this configuration we will enable this for the period of the 60-day trial (subject to unique license and customer configurations). Once the trial has ended your system will need to be reverted back to its original configuration. You will also need our newer LDK software protection. If you don't have this we can quote to migrate you for a small cost.

Complete the form below and we'll take care of the rest. Your appointed JETCAM representative will come back to you with a temporary license key.

Your JETCAM system will be reset to a temporary license code. If you choose to move ahead with UPN, we'll provide 'final' license codes. If you choose not to go ahead, contact your JETCAM representitive prior to the license expiry date and they will take care of reverting your license to its original configuration.

Requesting your trial

To find our more about UPN or to request a demo, please complete the form below: