YOUR CURRENT METHODS?

-

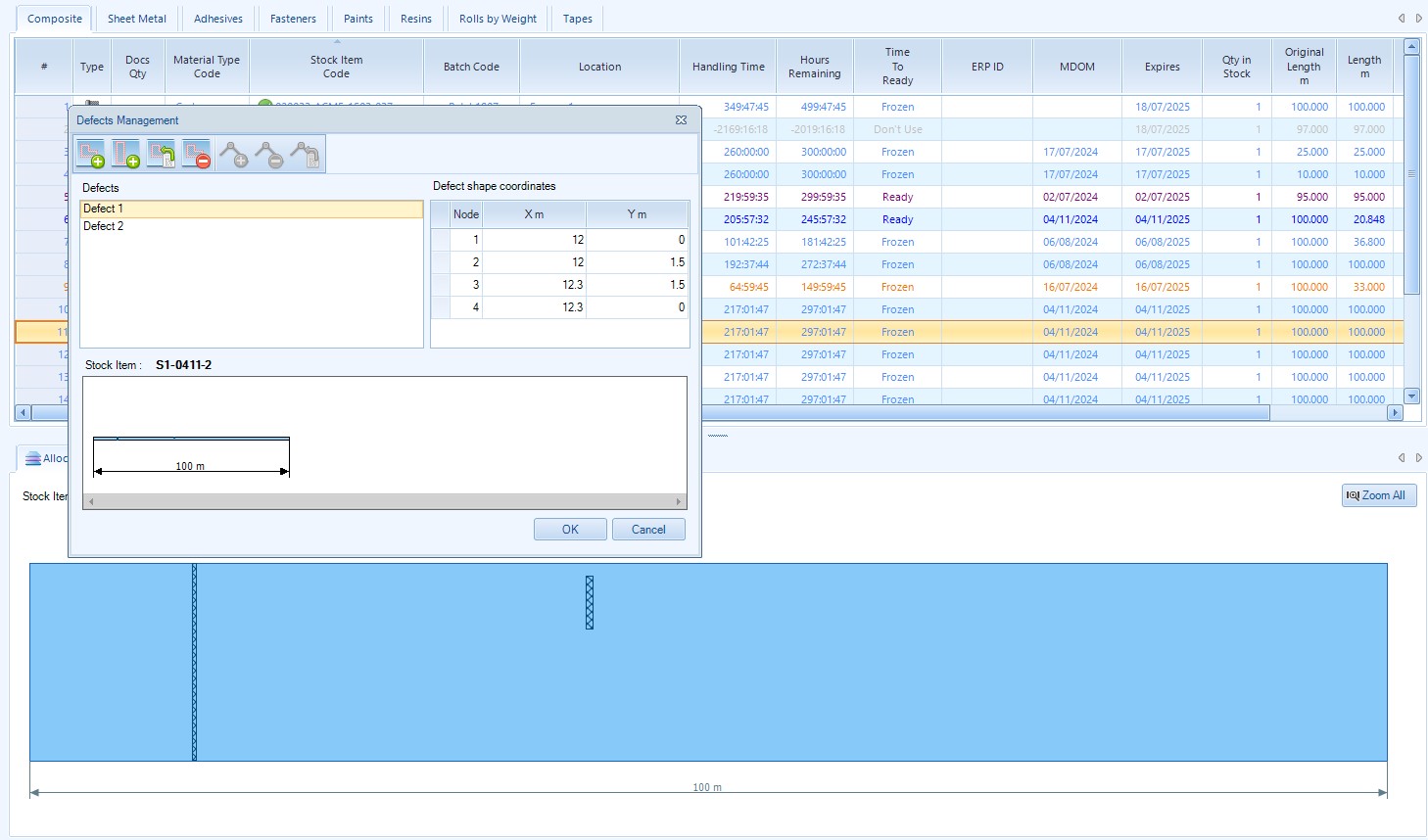

How much expired composite material do you throw away each month?

-

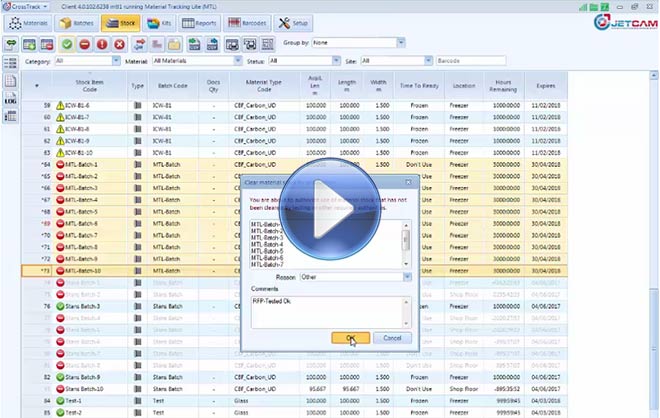

Do your staff always select the most appropriate material for a given job?

-

What amount of time and paper is used by staff to track material life?

-

How many errors are made when logging location or life?

-

Can you provide 'true' traceability reports to your customers? How long do they take to produce?

-

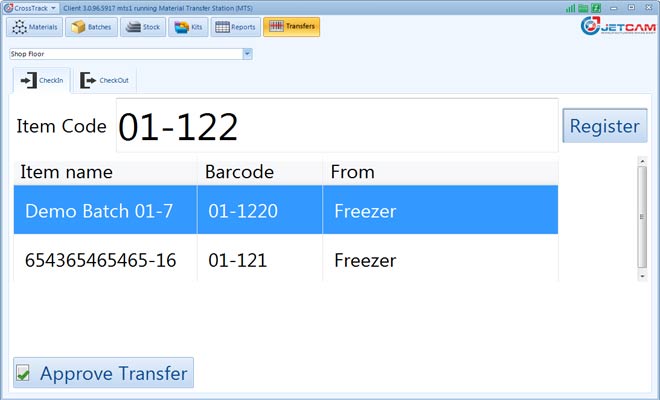

Can staff readily identify what items are in freezer(s) at any given time?

-

Do you want to get rid of paper, spreadsheets etc. that track composite materials innefficiently?

-

How many different systems do you have in place to track composite material life/location?